Businesses, especially those involved in the manufacture and sales of products, are heavily dependent on their supply chains.

Fortunately, developments in logistics and shipping have allowed businesses to tap into a global network of partners. They can now get materials and products directly from factories around the world at profitable prices.

However, despite these advances, supply chains still have to contend with the problems of inefficiency and waste. Issues in the supply chain can have an impact on the quality of products and materials particularly when shipments involve volatile, perishable, and sensitive goods such as pharmaceuticals, food, and electronics.

It’s estimated that a shocking of food products in the US is wasted through the supply chain. US retailers also lose annually due to returns, a portion of which can be attributed to damaged goods.

For companies, it has become all the more important that their goods go through the supply chain not only unscathed, but in the best shape they can be.

Shipment monitoring company looks to help companies and their supply chains become much more efficient through a tech-driven yet cost-effective solution.

“Today’s businesses can really go global. They can tap into a global network of suppliers and shippers to source and send just about any product anywhere.

But supply chains aren’t perfect. Problems can occur at any point resulting in waste. We want to make a difference by providing a powerful, scalable means for companies to monitor the condition of their shipments at any point in their supply chain,” Logmore CEO Janne Juhala said.

Issues across the supply chain

The old adage “Haste makes waste” still rings true today. However, considering how companies are pressured to get products moving through the supply chain at the quickest time possible, care is often compromised for the sake of speed. In their rush, shippers can become careless in how they pack products, making shipments susceptible to damage and breakage during transport.

Warehouse personnel and couriers can also be rough in their handling given the volume of packages they have to sort and deliver.

For volatile and perishable goods, businesses rely on cold chains which use climate controlled vehicles and storage units to keep the products within optimal conditions.

These cold chain machinery and components can sometimes break down, affecting their ability to maintain the right conditions.

Many countries have health and safety regulations that dictate that goods exposed to suboptimal conditions may be deemed unsafe and must be discarded or destroyed.

Waste inevitably impacts businesses, whether it’s through the costs of wasted goods or the time and effort spent to deal with them.

Companies should look to minimize the impact of these events and monitor the status and conditions of their shipment at all times.

“Speed counts in today’s supply chains, but service quality shouldn’t be compromised in the name of delivery speed. Shipment monitoring lets companies know about issues as they arise. By acting quickly, companies can fix issues before they become even larger problems,” Juhala continued.

How Logmore improves supply chains

Logmore looks to help address these issues by providing companies with a capable shipping monitoring system to use in their supply chains.

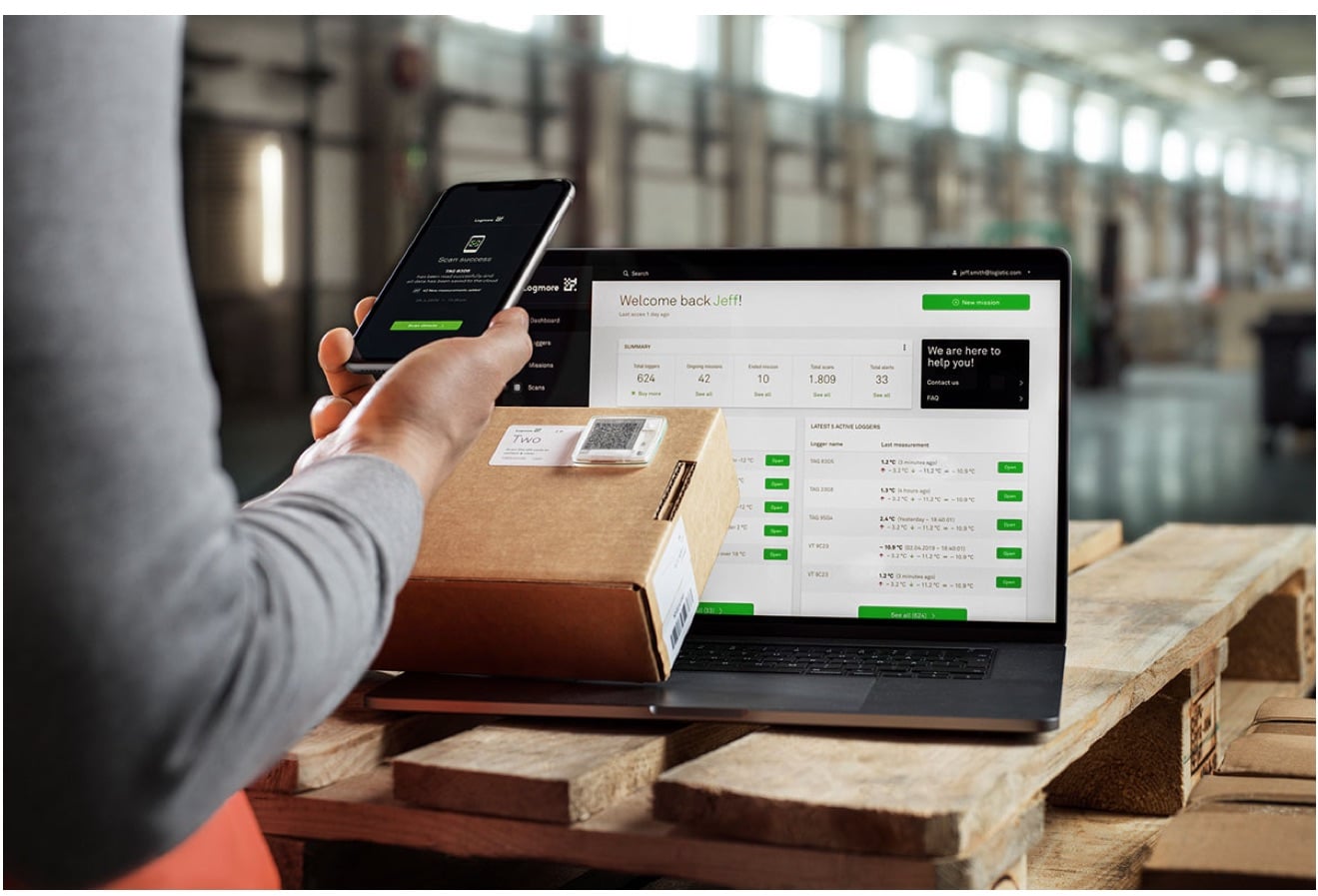

The company offers dynamic QR tags that can be readily placed with any product being shipped. These tags have built-in sensors that can log data such as temperature, humidity, ambient light exposure, shocks, and scanning location.

These data can be used to check if the shipment has been kept within optimal conditions while in transit.

What makes Logmore’s tags handy is that they feature dynamic QR codes. All the logged information is contained in the QR code which changes every time new information is gathered.

The tags can be scanned using a smartphone or QR code reader, unlike other loggers that require special hardware to extract the logged data. The scanned QR tag information is sent to Logmore’s cloud services which users can then access through a web interface.

Through the data, the company can readily know if there are worrying issues that may affect a particular shipment. Immediate intervention can readily be done.

For instance, the company can recall a badly handled shipment immediately rather than have the package move further down the chain where returns would be more costly.

The company’s network of partners can also be granted access to information, allowing them to see how they perform in handling the packages.

By having timely and accurate information, companies and their partners can identify the causes of issues and work toward improving and streamlining their supply chain processes and protocols.

Couriers that consistently mishandle goods can be replaced. Cold chain vehicles and facilities where the QR tags log suboptimal conditions can be readily checked for faulty equipment and repaired, thus preventing future wastage.

Less waste, better business

A well-managed and efficient supply chain should be able to minimize waste, allowing companies to enjoy various benefits. Less waste means companies can save on the costs associated with dealing with waste.

Better handling also means that customers get their products in the best condition possible.

Customer satisfaction can lead to repeat business and even referrals and recommendations. A better bottom line makes businesses more stable and resilient, which, in today’s competitive business landscape, could make all the difference.

“We help companies improve their supply chain efficiency and performance. Our easy-to-implement, scalable solution provides timely and accurate data on shipment conditions.

That data helps businesses cut down on waste to deliver better quality to their customers, and achieve sustainability, profitability, and success,” Juhala concluded.

Be First to Comment